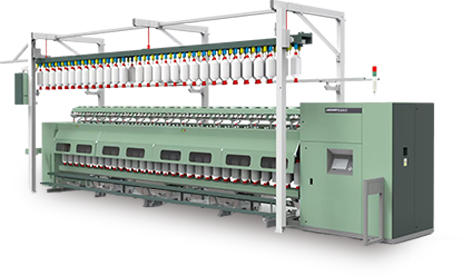

HCP2030智能粗紗機(jī)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>

Product Performance

High end

Achieve new breakthroughs in spinning speed, efficiency, and number of spindles, leading the development of the roving machine industry.

Greening

Energy saving, low-carbon, and environmentally friendly design.

Intelligence

Integrated design of electromechanical hoses, equipped with a large database of experts, to achieve intelligent spinning.

Electronic Process

Electronic process, eliminate all process gears.

Improve drafting accuracy

Realize stepless adjustable stretching ratio with an accuracy of 0.001, avoiding stretching interference caused by gear matching in traditional models.

Improve production efficiency

Electronic stretching reduces additional stretching, reduces weight unevenness and breakage rate, and improves the quality and efficiency of the yarn.

High RPM

The average process speed of the spindle can reach over 1250r/min.

Separate control of segmented transmission

The distribution of power transmission points is more uniform, and the control system is precisely regulated to improve spinning quality.

High transmission efficiency

Drive efficiency increased by 15%.

Each group of simple management is individually controlled

The distribution of spindle wing power transmission points is more uniform, and the control system precisely regulates the simple tube, significantly improving the quality of spinning.

Low noise

The noise level during full load operation is ≤ 65 decibels.

Product Advantages

More flexible

The spinning unit of the roving machine can be infinitely extended, perfectly matching the long frame of the spinning machine.

High speed

The upper Rail tendon is driven by a multi motor synchronous belt, with an average spinning speed exceeding 1250r/min.

HCP2030智能粗紗機(jī)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>筒紗智能柔性包裝線(xiàn)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]> ?

?

筒紗智能柔性包裝線(xiàn)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>智能立體倉(cāng)儲(chǔ)系統(tǒng)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>

.jpg)

Product advantages

1、 Improve space utilization

The improvement of land utilization rate has reduced the area occupied by warehouses, thereby reducing the investment cost of infrastructure land, saving resources, and enhancing environmental protection efforts.

2、 Improve the quality of goods storage

In the process of inbound/outbound operations and cargo scheduling in automatic stereoscopic warehousing, the combination of vertical storage and roadway settings, coordinate management, and computer management system are used to achieve real-time control of goods, efficient and accurate inventory counting, making material flow faster and ultimately improving the storage quality of goods in all aspects. In addition, the probability of cargo loss caused by human factors is reduced during the storage and retrieval process, thereby ensuring the safety of cargo storage.

3、 Improve production efficiency

Automated three-dimensional warehousing can accurately realize the entry, exit, re entry, inventory counting, inventory verification, and display of goods. It also timely and automatically sends pallets to the production line and finished products to the exit area, ensuring that the warehouse has the ability to quickly enter and exit goods. This feature is beyond the reach of ordinary warehouses.

4、 Beneficial for building advanced logistics systems and improving the production management level of enterprises

In logistics costs, warehousing and logistics costs account for a large proportion and are a golden location that cannot be ignored in third-party profit sources. The expansion of automated three-dimensional warehousing has expanded the single storage function of traditional warehousing, enabling efficient operation and management of materials (mainly through the use of computer management systems and automated material handling equipment), transforming goods from "static storage" to "dynamic storage", and forming an intensive information flow. It is a link in the production process and an indispensable part of enterprise logistics, providing necessary precision basis for management decisions.

1.jpg)

Our company applies the concept of modern logistics development, with logistics information technology as the core, and adopts advanced simulation systems and finite element calculation theory to provide customers with high-quality logistics planning, meticulous design, European standard technology, and comprehensive turnkey projects. Facilitating the formation of advanced logistics systems and improving the production management level of enterprises.

2.jpg)

1、 Single extension tray storage system

There are two types: single column and double column, with a maximum unit weight of 4 tons and a maximum height of 40 meters

2、 Dual extension tray storage system

Using a double extended fork, the maximum unit weight is 1 25 tons, the stacker crane can carry 2.5 tons and has a maximum height of 35 meters

3、 Dual pallet storage system

The stacker crane uses two forks or takes two pallets at a time in the direction of the fork extension.

4、 High density pallet storage system

The shuttle board can be used in conjunction with stacker cranes or forklifts.

5、 Gravity based shelving and pallet storage system

The shelves contain non powered sticks, and the trays move forward by gravity.

No tray storage system.

3.jpg)

The pallet stacker crane is one of the important cargo storage and retrieval equipment in automated three-dimensional warehouses. The lifting capacity of a stacker crane is generally below 4 tons, and its operating height is generally between 10-40 meters. The stacker crane is equipped with anti sway devices, which make positioning more accurate. High strength steel is used to greatly reduce the weight of the stacker crane and save energy; The maximum operating speed of the stacker crane is 300 meters per minute, with higher efficiency.

Shuttle high-density storage and shuttle board

Shuttle high-density storage system: composed of shuttle shelves, shuttle carts, forklifts or stackers, this efficient storage method is designed to improve the utilization of warehouse space.

4.jpg)

Features:

High work efficiency, greatly reducing work time;

Good safety, reducing shelf collisions;

High density storage, warehouse utilization rate is 30% higher than that of aisle stacker warehouses

Flexible homework methods;

The storage and retrieval of goods can be done in a first in, first out or first in, second out manner.

A company that uses stacker cranes for fully automated high-density storage systems.

Scope of application

Shuttle shelves are suitable for industries such as food, beverage, chemical, tobacco, etc. with large quantities of single varieties and relatively few types of items; Suitable for cold storage operations, it can reduce low-temperature operation time, improve work efficiency and safety: suitable for warehouses that increase storage capacity, have limited storage space, and need to make the most of space.

Shuttle boards are divided into two types: 4-wheel shuttle boards for forklifts and 8-wheel shuttle boards for stackers.

A shuttle car is a type of track tray handling trolley, consisting of a running mechanism and a chain or roller conveyor. There are single track shuttle cars and double track shuttle cars for shuttle cars.

5.jpg)

AGV

Automated Guided Vehicle (AGV) refers to a transport vehicle equipped with electromagnetic or optical automatic guidance devices, capable of traveling along a specified guidance path, with safety protection and various transfer functions. In industrial applications, AGV does not require a driver and is powered by rechargeable batteries. Generally, its travel route and behavior can be controlled through a computer, or its travel route can be established using electromagnetic tracks, lasers, GPS, etc. Unmanned transport vehicles move and move according to the information brought by guided tracks.

Features:

AGV is characterized by wheeled movement and has advantages such as fast action, high work efficiency, simple structure, strong controllability, and good safety compared to walking, crawling, or other non wheeled mobile robots. Compared with other commonly used equipment in material conveying, the activity area of AGV does not require fixed devices such as tracks and support frames, and is not limited by the site or roads. Therefore, in automated logistics systems, their automation and flexibility can be fully reflected, achieving efficient, economical, and flexible unmanned production scheduling, while achieving seamless connection between equipment and WMS systems. Complete functions such as logic control, information exchange, data processing, and signal acquisition. Accept ERP system information and return information to the ERP system. Inventory information can be opened to other management systems.

6.jpg)

智能立體倉(cāng)儲(chǔ)系統(tǒng)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>智能搬運(yùn)機(jī)器人最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>The handling robot mainly adopts laser navigation, SLAM navigation, visual navigation and other methods. Through data fusion processing of various sensors such as LiDAR, camera, ultrasonic, infrared, etc., high-performance processors are configured to realize functions such as perception, mapping, matching and positioning of forklift environment. At the same time, combined with the supporting scheduling system, underlying control module and software development interface, users can complete the development and deployment of unmanned forklifts in various application scenarios.

機(jī)器人-1.jpg)

Clamping/forklift handling robot

The Global Gripper/Forklift Handling Series Robot, equipped with SLAM navigation, is the preferred product for implementing flexible solutions such as "intelligent cotton matching" and "network package warehouse connection" in spinning factories.

? A powerful traffic dispatch system that enables multiple dispatch machines;

? Navigation accuracy 1cm

? Pick up positioning accuracy ± 5mm

? Suitable for handling pallets of different specifications, with a rated load capacity of 1 ton and 1.5 tons

? Speed can reach 60m/min

? Automatic charging function

Integrate with upper management systems such as MES to achieve data statistics

Cleaning Robot

The Global Cleaning series robots, equipped with SLAM navigation, are the preferred products for achieving ground cleaning in spinning factories and reducing labor costs.

? Powerful SLAM scene map construction

? Navigation accuracy 1cm

? Automatic garbage collection for cleaning

? Automatic charging function

Continuous working hours of 8 hours

Barrel handling robot

The Global Barrel Handling Series Robot, equipped with SLAM navigation, is the preferred product for implementing flexible solutions such as "comb parallel connection" and "parallel coarse connection" in spinning factories.

? Powerful traffic dispatch system, achieving multiple dispatch

? Navigation accuracy 1cm

? Can adapt to strip tube diameters of 500mm, 600mm, 1000mm

? It can be transported directly by dragging the tube, or lifted and transported.

? Speed can reach 72m/min

? Automatic charging function

? Intelligent position recognition and identification of the strip tube, with a positioning accuracy of up to ± 5mm

Integrate with upper management systems such as MES to achieve data statistics

智能搬運(yùn)機(jī)器人最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>CMT1801全自動(dòng)落紗粗紗機(jī)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>

Efficient and energy-saving, highly automated, labor-saving, and low maintenance costs

Global fully automatic yarn shedding machine and automation solution:

Safe, reliable, efficient, and energy-saving

The longest spindle count can reach 240 spindles, and the yarn shedding parking only takes 2 minutes

The CMT1801 fully automatic yarn shedding and roving machine has a high global sales volume and has equipped over 10 million spindles for domestic and foreign customers. The success rate of yarn shedding, head shaking, and air traffic control exchange is almost 100%, and it is very easy to use and maintain. Truly digital, intelligent, and continuous equipment, with a maximum capacity of 240 spindles.

characteristic

Maintaining and repairing the yarn dropping system does not affect the normal operation of the spinning system - it has good efficiency.

The success rate of yarn shedding, air tube replacement, and head replacement is close to 100% - high success rate.

Adopting synchronous control of 7 motors - true human-machine dialogue.

Multiple roving machines networked system, centralized management, remote diagnosis, and improved production efficiency.

CMT1801全自動(dòng)落紗粗紗機(jī)最先出現(xiàn)在青島環(huán)球集團(tuán)。

]]>